|

Hangzhou Zhongyuan Machinery Factory Company

|

c purlin roll forming machine roll forming machine for purlin

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Heat - treated Purlin Roll Forming Machine 100 - 300mm 10 -12m / min , Metal Shaping Machine

Heat - treated Purlin Roll Forming Machine 100 - 300mm 10 -12m / min , Metal Shaping Machine

Feature of Z Purlin roll forming machine

One machine can produce different sizes of purlines.

Technical data of Z purlin roll forming machine

|

Suitable Material |

Cold-rolled steel strip and heat-treated galvanized steel strip |

|

Thickness of raw material |

1.5-3.0mm (235-345Mpa) |

|

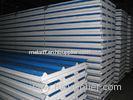

Size of Z purlin |

100-300mm adjustable (special size available) |

|

Material of roller |

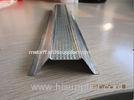

Cr12 mould steel being quenched treatment,HRC58-60 |

|

Material of cutter blade& punching die |

Cr12 mould steel with quenched treatment, HRC58-60 |

|

Material of shaft |

High quality 45# steel with heat treatment. Roller grinder milling. |

|

Forming speed |

about 10-12m/min |

|

Power Requiremen |

Main motor power: 15 Kw(Depend on final design) |

|

Hydraulic station power: 5.5Kw (Depend on final design) |

|

|

Diameter of shaft for rollers |

82mm |

|

Controlling system |

Mitsubishi PLC & converter |

|

Quantity of rollers |

about 15 stations for main rollers |

|

Weight of machine |

About 9000KGS |

|

Size of machine installation |

About 19 m x 2.3 m x1.5m |

Product application of Z shape purlin roll forming machine

They are widely used as the supporter of roof and wall in large-scale and mid-scale construction, such as factory, warehouse, garage, exhibition center, cinema, theatre, garden and so on.

Our Metal Z shape Purlin Roll Forming Machine’s advantages

1. Anti-rust roller: Cr12 mould steel with quenched treatment, long life time.

2. Heat treatment: Heat treatment for cutting frame to remove the steel stress, to avoid deformation.

3. Cutter blade: Cr12 mould steel with quenched treatment, long life time.

4. High precision: shafts for rollers are tooled by grinding machine at least twice. Rollers are CNC processed to ensure precision performance.

5. People originate: introduced Mitsubishi PLC with touch screen. Friendly man-machine interaction.

6. Excellent services: Technician can be sent to your factory to install the machine and train your workers. Lifttime services for our machines.

7. All-in-house source: We are "All-in-house source" factory to ensure quality and delivery of your machines.

8. Long life: Ensure you our produce machine’s lifetime more than 15 years.

Certificate: ISO 9001, CE